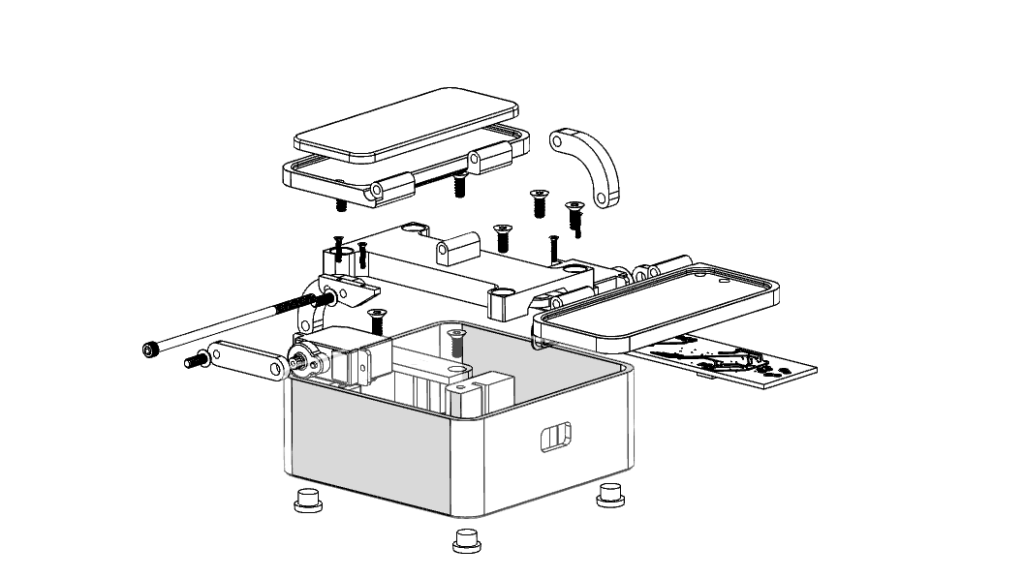

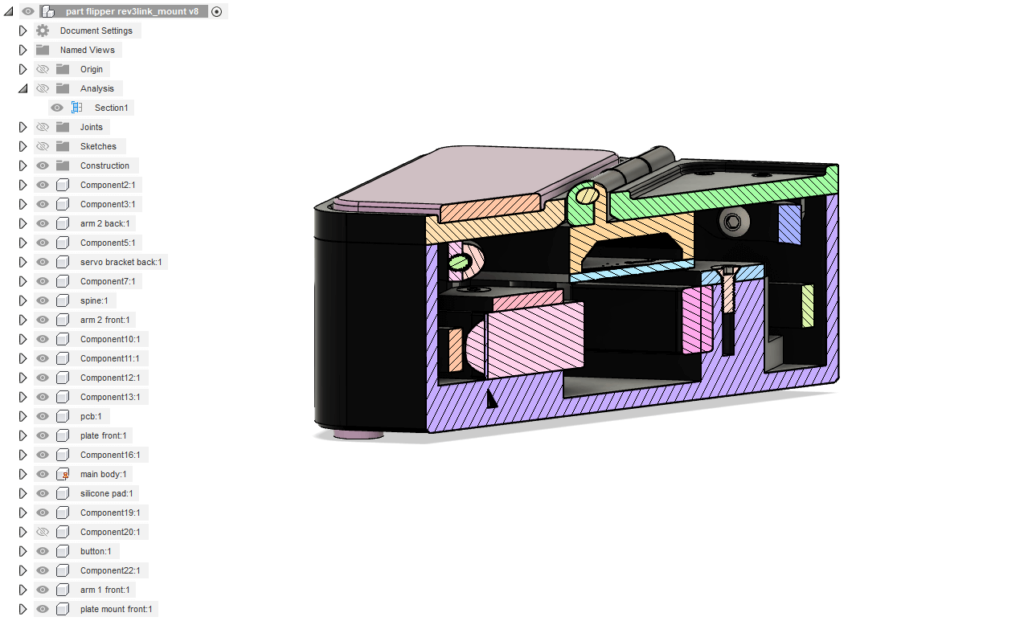

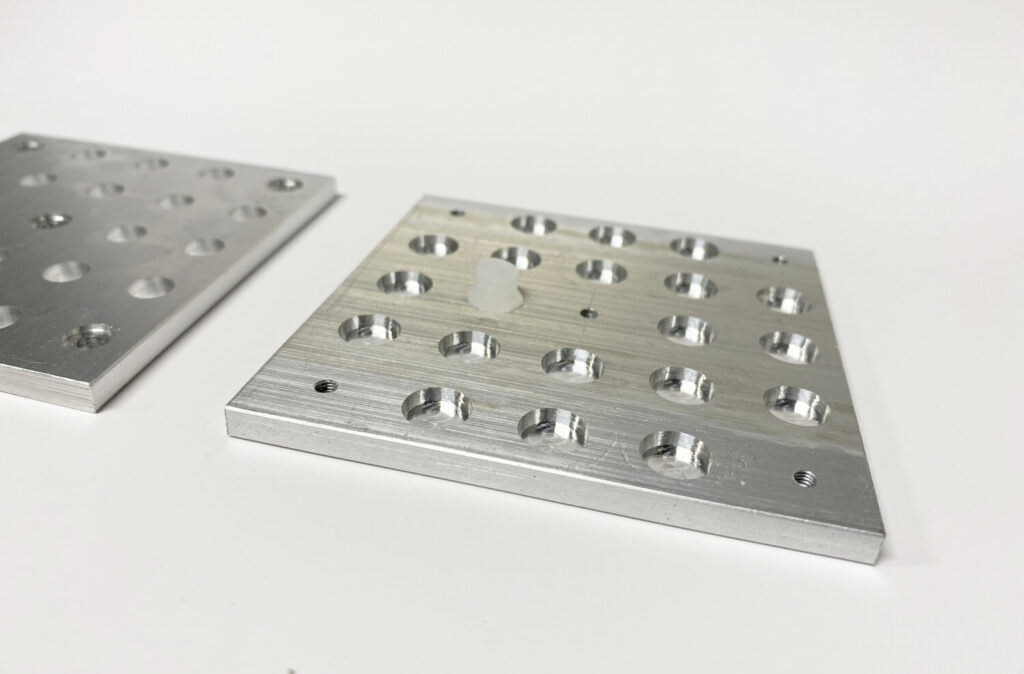

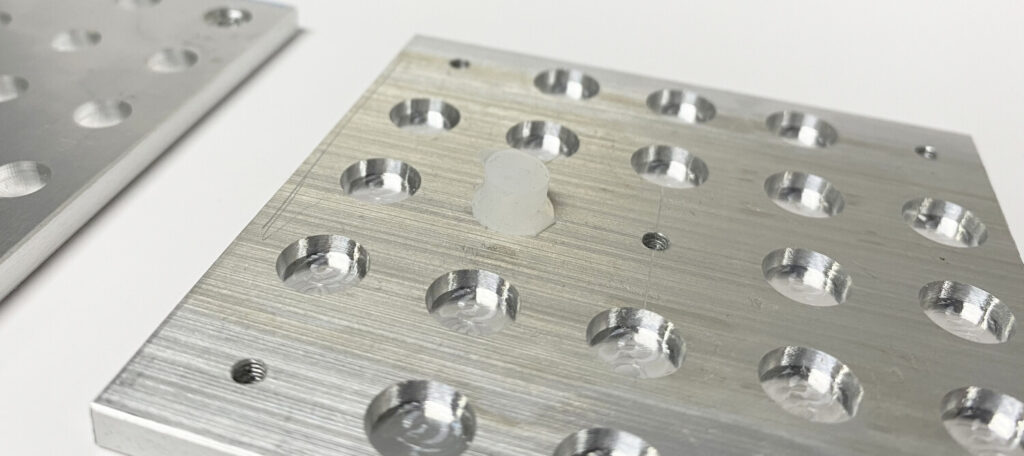

I made this as a simple single purpose tool to aid in inverting parts that are upside down when assembling PCB’s by hand. The component are first dumped into the front tray, all right side up parts are then placed, the button front is then pressed to clam shell the back plate forward, both move in unison to the back and finally the front plate opens to revile the remaining parts right side up.

Project reboot:

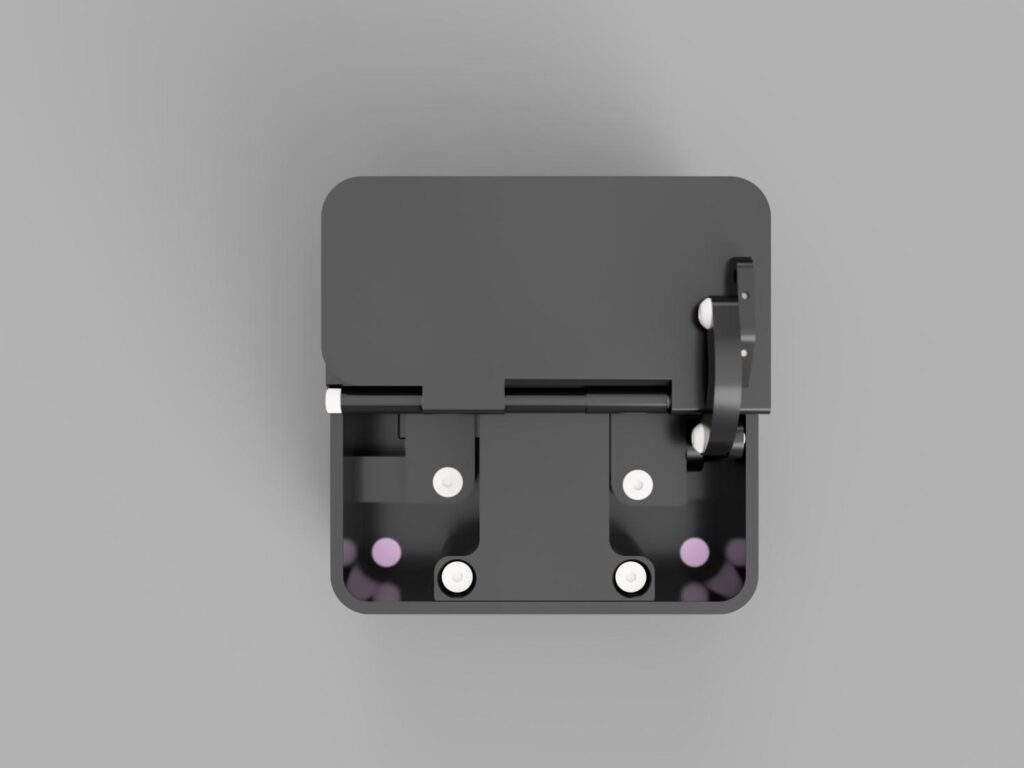

The servos are just not smooth enough move to either the n20 brushed motors like the pick and place feeders or brushless but the n20 are probably the best right now since they have a gearbox already. a couple ideas are either a friction drive to avoid precise control of the motor or a simple 2 gear system that uses motor current sensing for limit determination. you can have the rgb show charge level on the front and the device can have just the front button when you push it it wakes from deep sleep will move then go back to sleep, deep sleep should retain it its a front to back or a back to front you can probably fit a decent battery like 1000 or 800mah. the button should also be set back a little and angled so the push force is half z and half x axis, possible also zigbee or wireless like BLE (is it usefull)

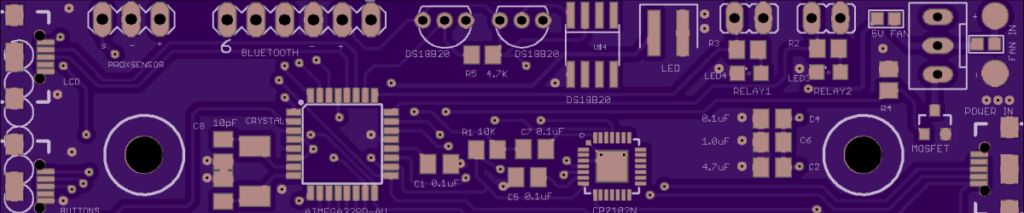

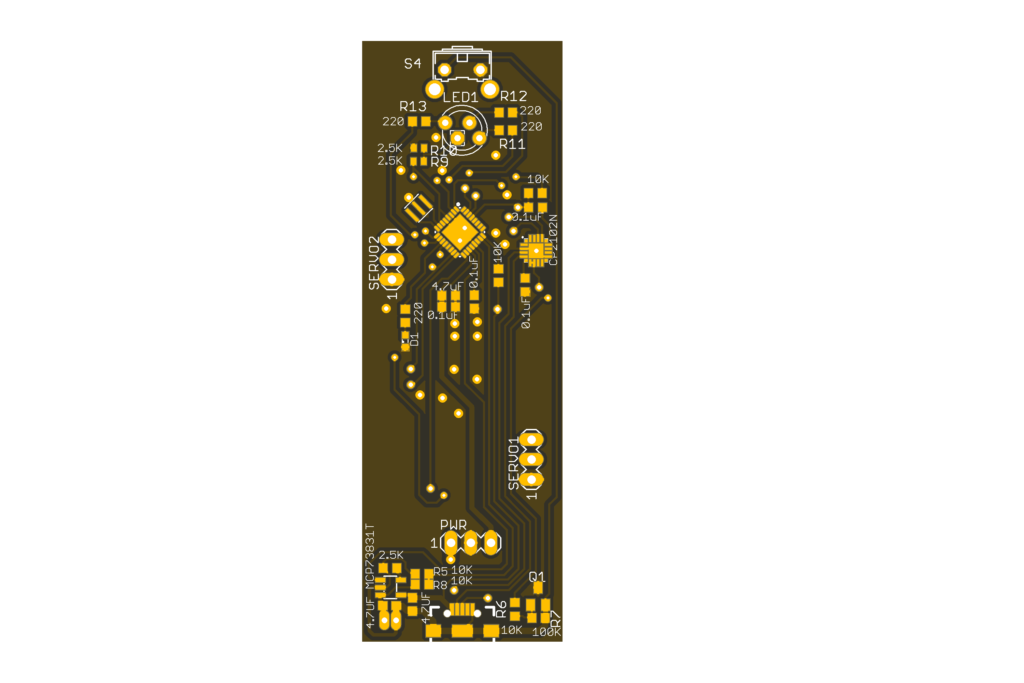

PCB Scope:

micro-

RGB-

softlatch-

battery charging-

2x motor controllers-

usb-c-